Due to considerable rotational torque may sometimes damage the blades of CSGL agitators, our experts can replace the impellers with PFA lining, which is more durable against high torque. High rotating friction causes damage to Hastelloy-C sleeves in these circumstances, but we can also replace Hastelloy-C sleeves with respect to single or double mechanical seals.

By monitoring run out and shaft RPM, our engineers additionally supervise installation and work following delivery at your site.

Threaded Design Brief:

Threaded design make it possible for agitator to be installed inside the reactor from the manhole without having to open the COC. Threads 135 MM long at the shaft and impellers connect the conjunction in the design of kind agitators. A tight-fit mechanical allowance at the connection junction is made possible with the engineering skills of our technical experts, and it offers the functionality as required during applications. Threads with rotational direction that should rotate either clockwise or anticlockwise are according on the requirements of the user.

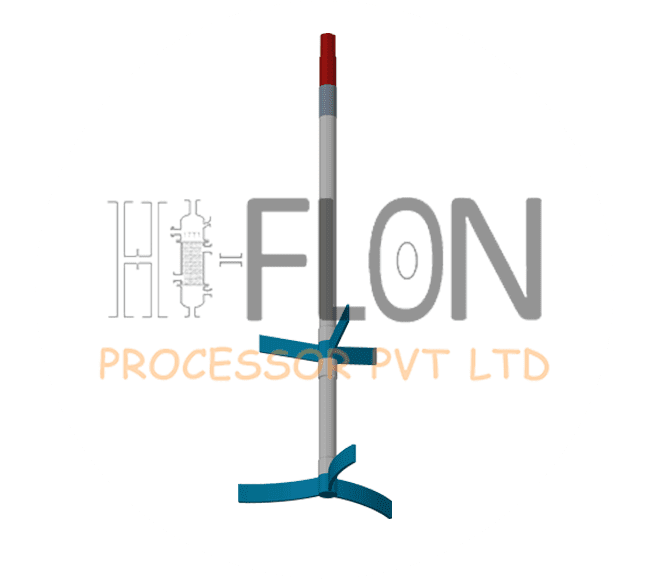

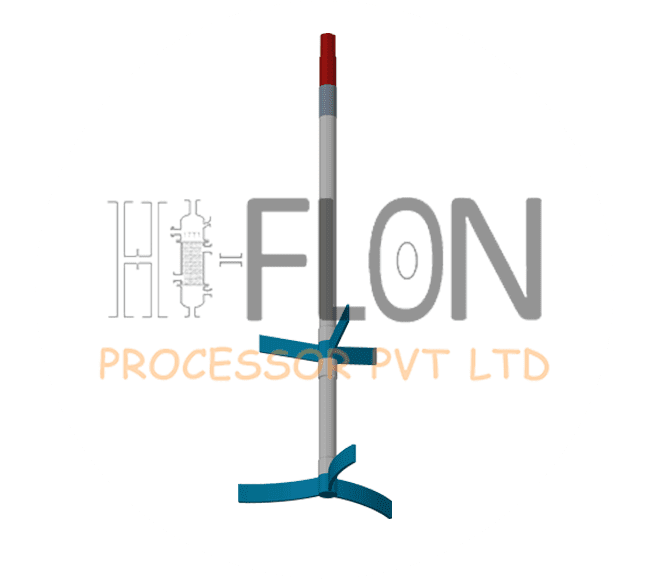

• Single-Stage Impeller Type Propelling Agitators.

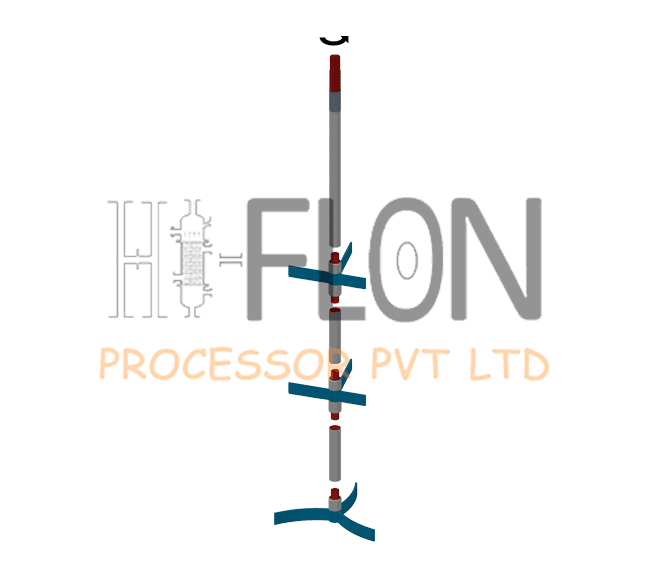

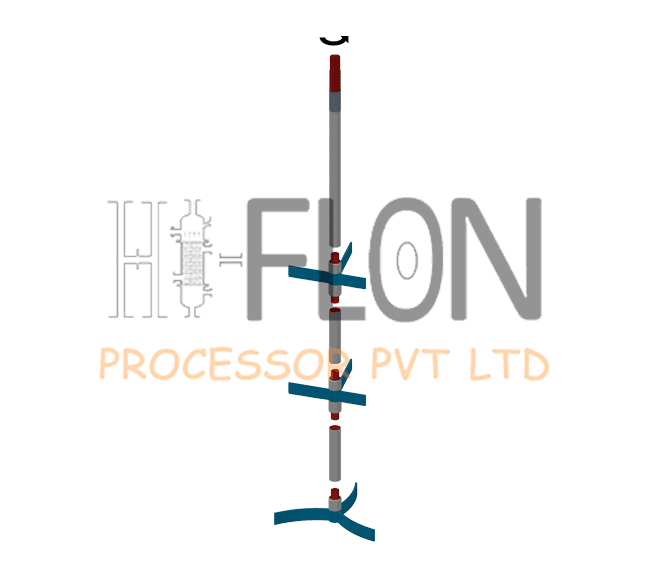

• Two-Stage Impeller Type Propelling Agitators.

• Multi-Stage Impeller Type Propelling Agitators

Benefits and Features of Hi-Flon Design

Product development is regulated by ASTM F1545-compliant lining, STD SCH-XXS pipe for shafts, and IS2062 plates for impellers.

5 MM–6 MM

Impeller Sweep Diameter (Swing Over): 750 MM to 1100 MM (Sweep Extenders are provided for diameters above 1100 MM) According to the requirements of the user, shaft lengths possible from 1 to 6 meters are appropriate for single-, two-, or multi-stage applications.

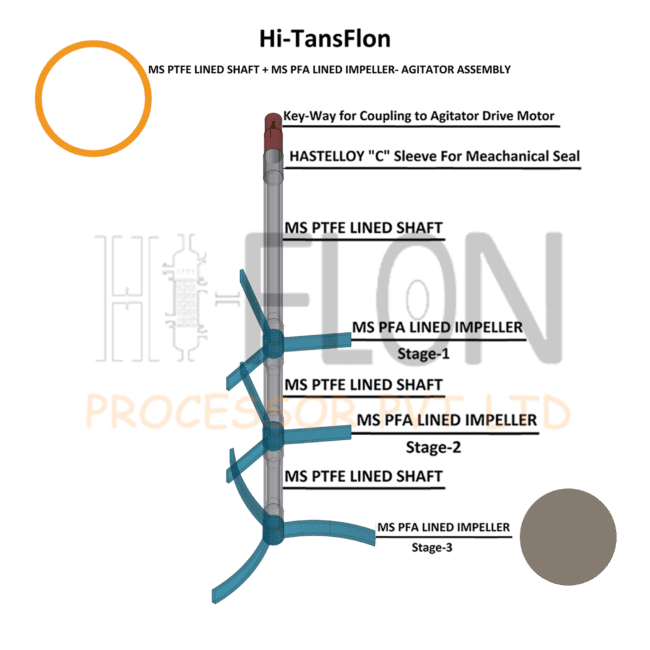

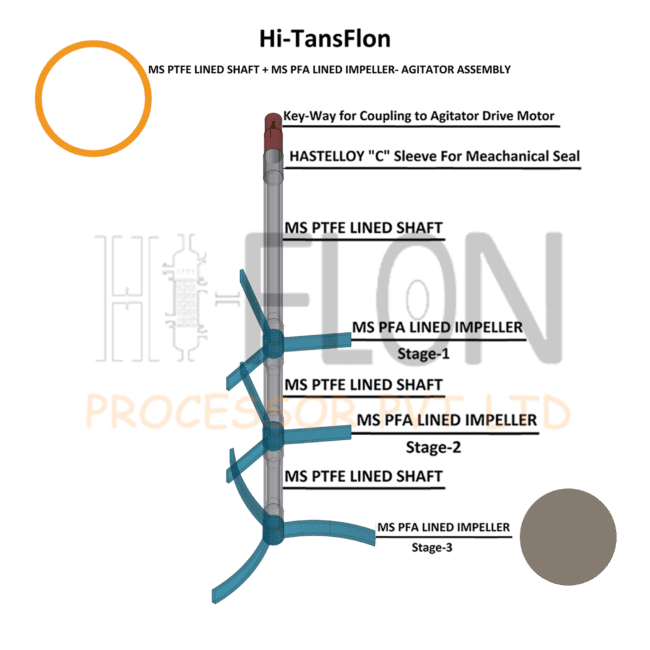

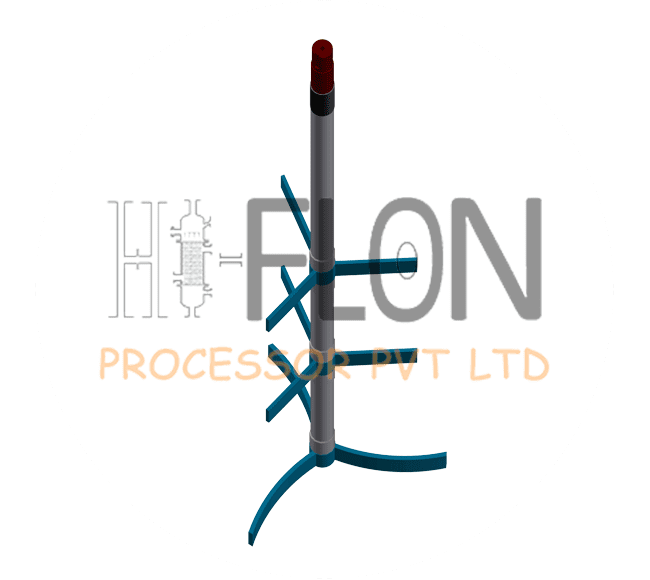

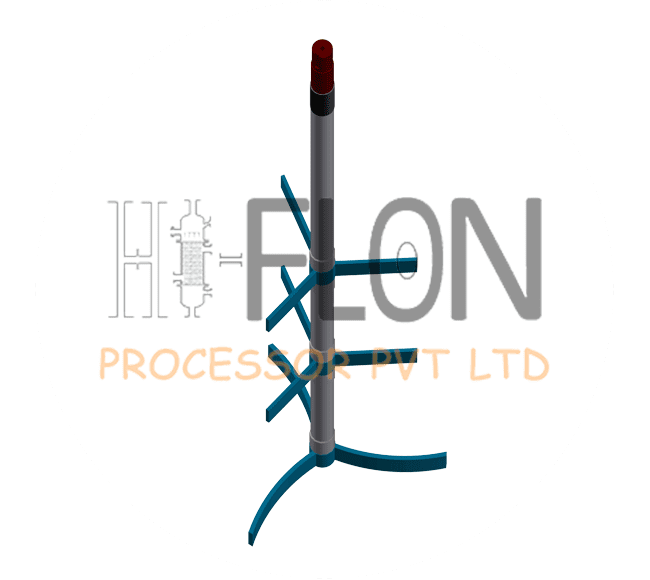

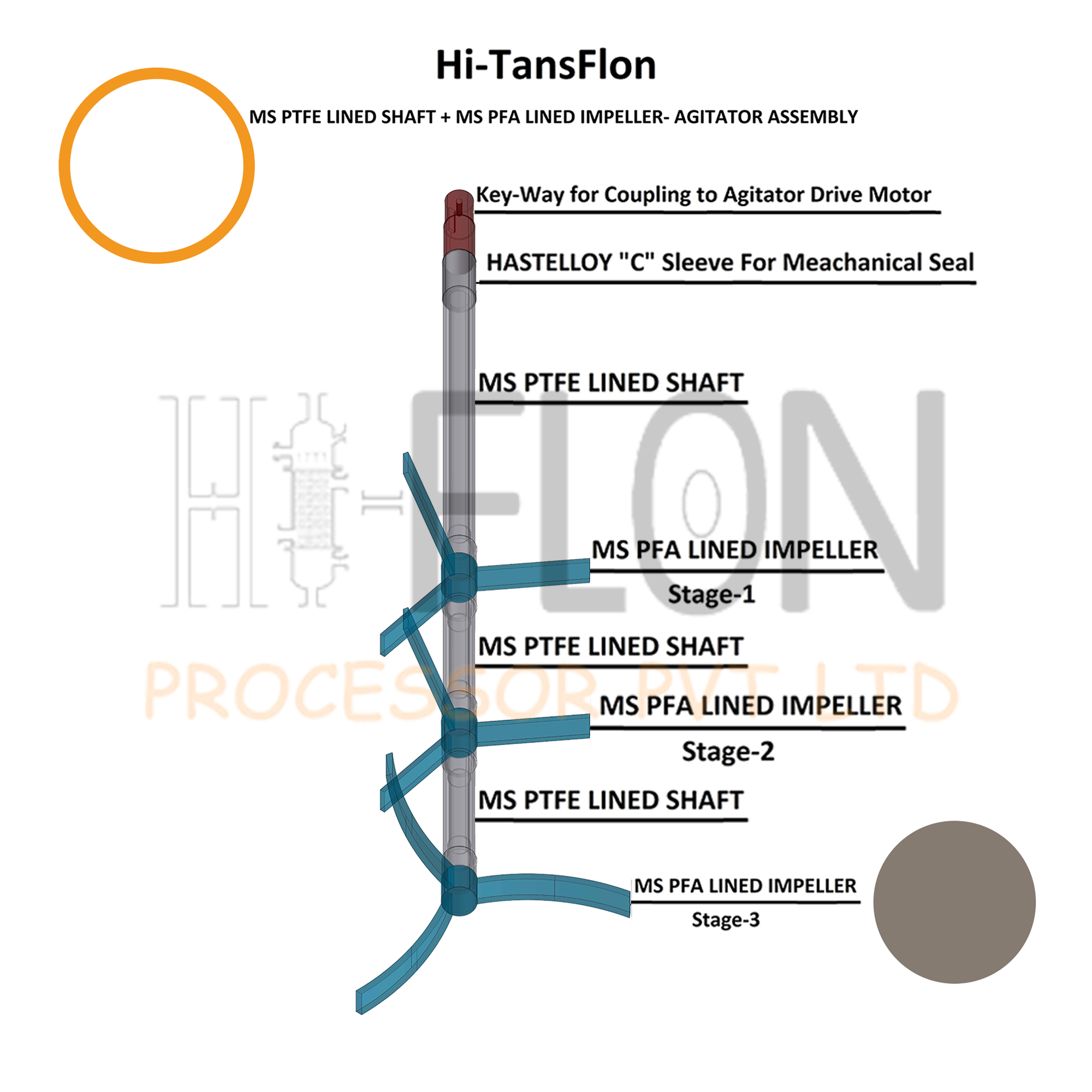

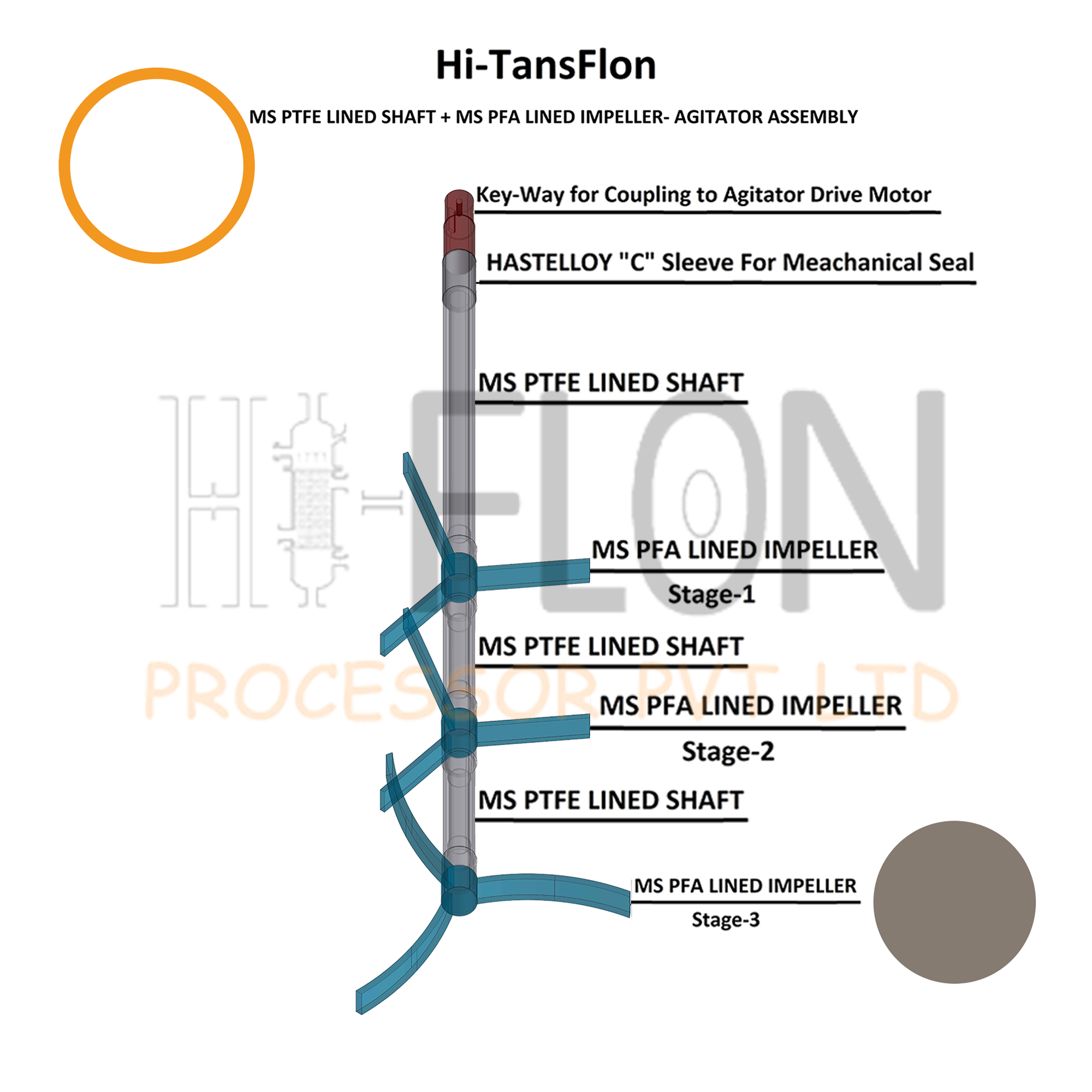

We offer various design in CS Fabricated PTFE Lined Shaft & PFA Lined Impeller Agitator with One-Piece Design as shown in above image. We can design Agitators in Single stage Impeller, Two Stage Impeller & Multi Stage Agitator Impeller with 3-Blade& 2- Blade option in each stage.

Above Image represent 3-Stage 3-Blagdes CS Fabricated PTFE + PFA Lined Agitator.

Our engineers are able to design impellers in Radial Blade (90°) or Pitch Blade (45°). In Pitch blade design we can develop Up Pumping or Down Pumping Manners As per User applications.

Our Technical Team also provides Torque Rating, Bending Moment based on RPM of the shaft & Motor Speed; it makes easier to recognize for suitable working conditions.

We can also able to replace only Impellers from CSGL Agitator. In CSGL Agitators sometimes Blades become damage due to high rotational torque; so our experts can be replace Impellers by PFA Lining. In Such case Hest Alloy ‘c’ Sleeves also become damage due to High rotational friction; we can replace also Hest Alloy ‘C’ Sleeve with respect to single or double mechanical seal.

Our Engineers also guide for Installation and working after delivery at your sight by checking Run out and Shaft RPM.

5 MM – 6 MM

Transfer Lining & Sleeve Lining.

For Impellers Sweep ø (Swing Over): 750 MM to 1100 MM. (Above 1100 MM Sweep ø Extenders are available to achieve)Shaft Length: As per user requirement.

Spark Test: 15 KV to check isolate metallic contacts after lining.

Suitable For Full Vacuum -1 BAR to high pressure +6 BAR.

Location

E-503, Sumel-11, Nr Namaste Circle, Shahibaugh, Ahmedabad-380004, Gujarat.