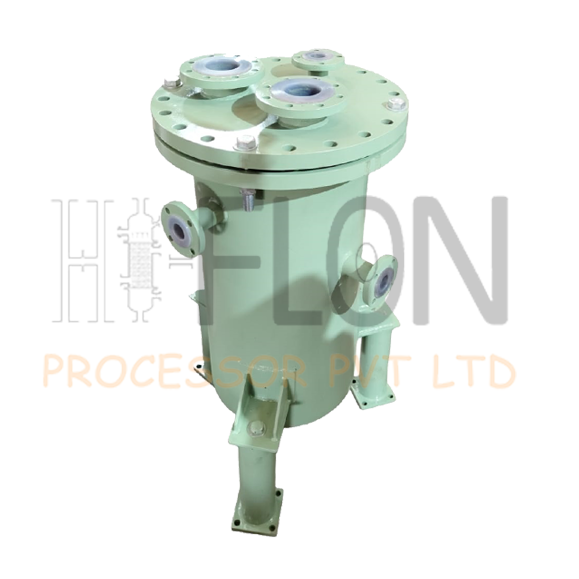

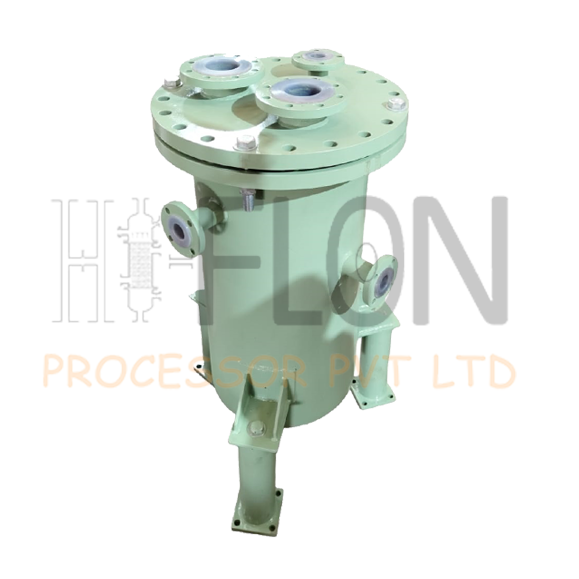

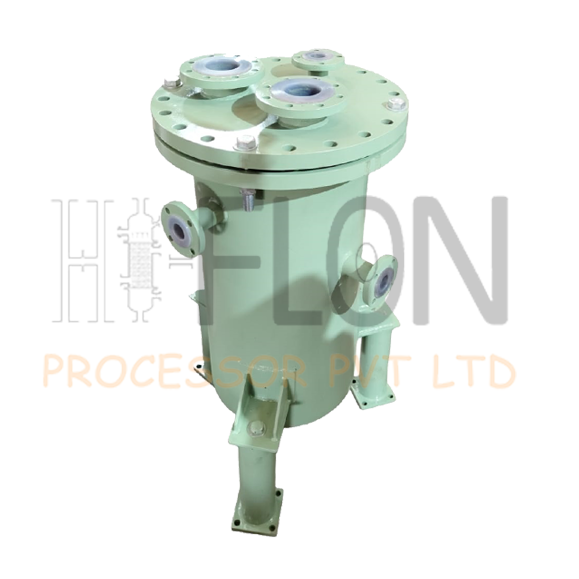

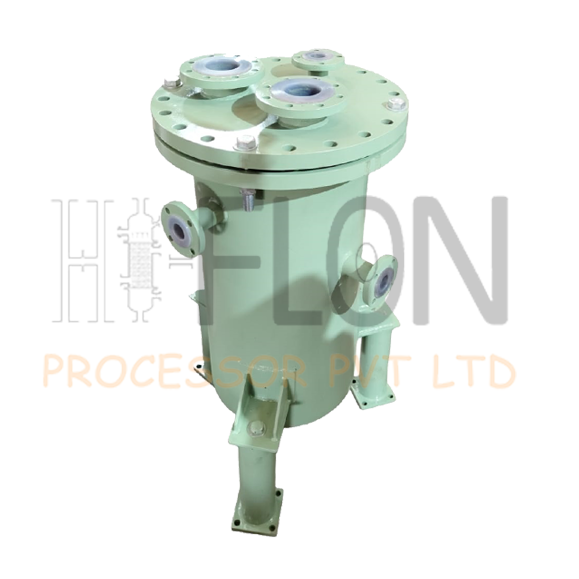

In corrosive fluid applications at high temperatures, a CS-fabricated PFA-Lined Header with the following function is used: Uses to reduce flange joints from the gathering junction pot to the supply direction in a pipeline system, thus preventing leaks and spills from the gathering junction.

A Standard Quality Assurance Plan is followed throughout the production process, from raw material to finished product, and the product is verified at each stage by certified Supervisors and Inspection engineers. Various tests, such as hydrostatic pressure testing, dimensional checking, pressure drop testing, and so on, are carried out as applicable.

Our process designers and product development engineers provide process data sheets to match the best-suited design with its GAD for applications. In addition, lining vents as per pipe standards are supplied in the housing body to evaluate user fouling of the segments over long-term usage.