Various tests, such as hydrostatic pressure testing, dimensional verification, and pressure drop testing, are performed as needed. Process data sheets are provided by our process designers and product development engineers to match the best-suited design with its GAD for applications. In addition, lining vents as per pipe standards are supplied in the housing body to evaluate user fouling of the segments over long-term usage.

Benefits and Features of Hi-Flon Design:

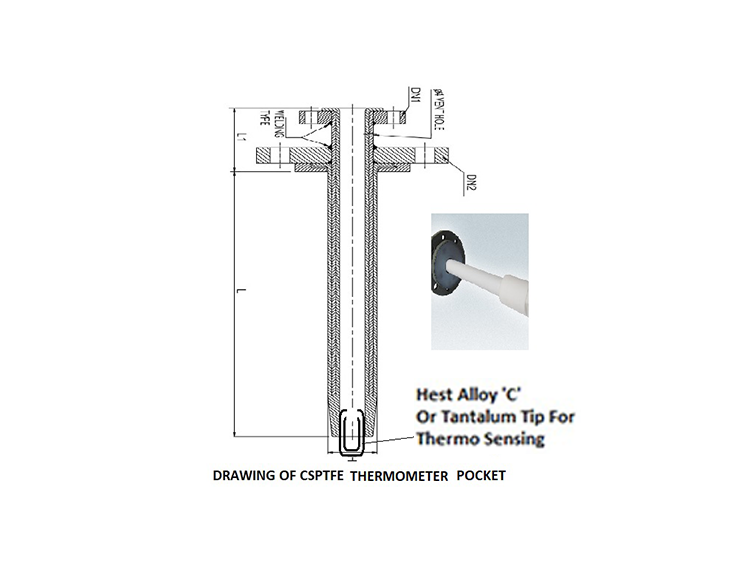

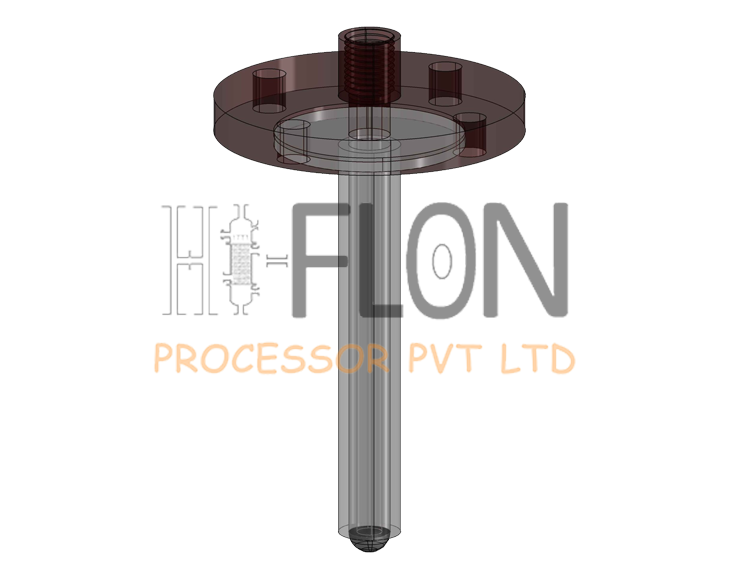

Product development is subject to ANSI B 16.5 ASA#150 of IS2062 for flanges & ANSI 36.10 ASTM A-106 Grade B SCH-40 for Pipe with internal lining conformance to ASTM F1545.

5 MM–6 MM & in nozzles accordance to ASTM F1545

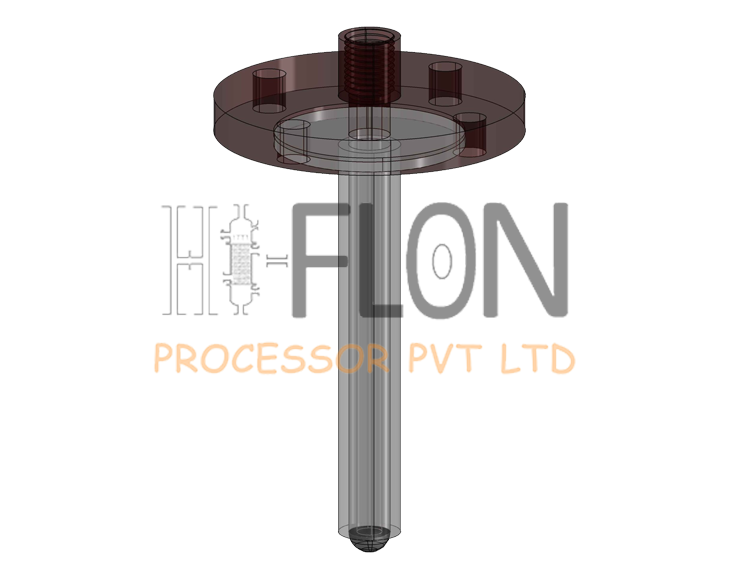

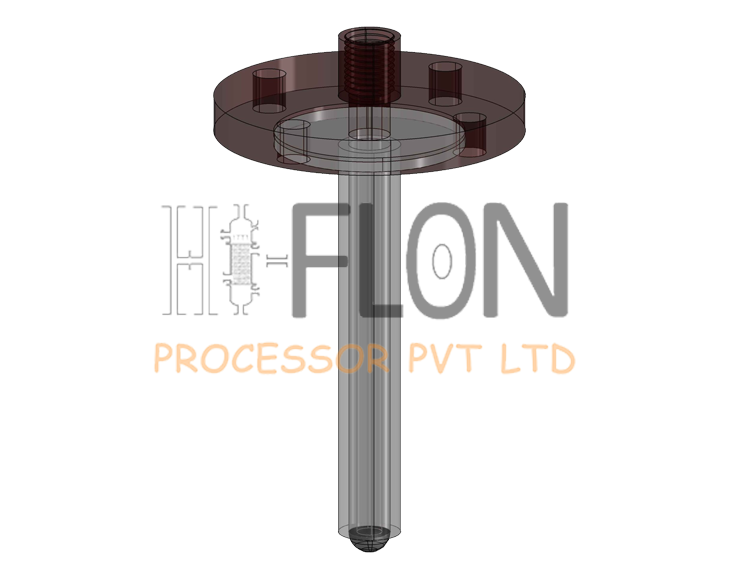

We offer various design in CS Fabricated PTFE Lined Tharmo meter Pocket as shown in above image. Also Available in Antistatic PTFE Resins.

5 MM – 6 MM

Location

E-503, Sumel-11, Nr Namaste Circle, Shahibaugh, Ahmedabad-380004, Gujarat.