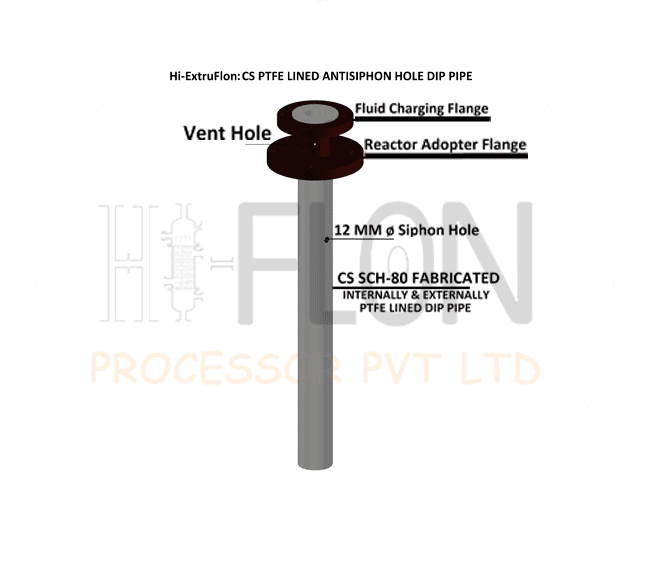

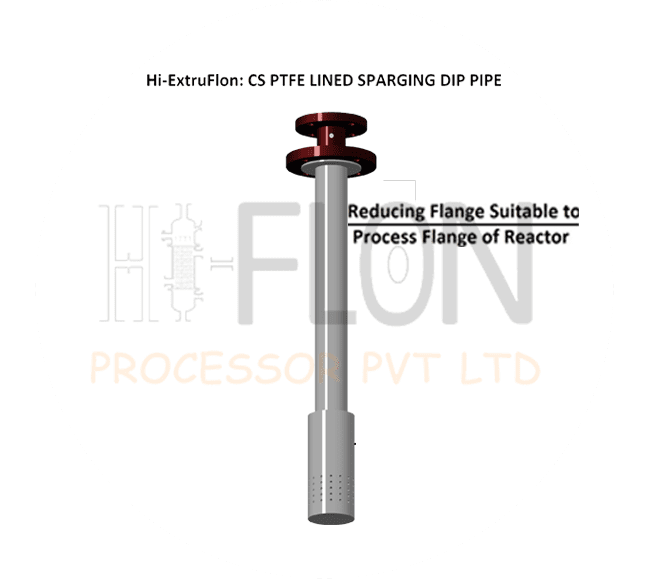

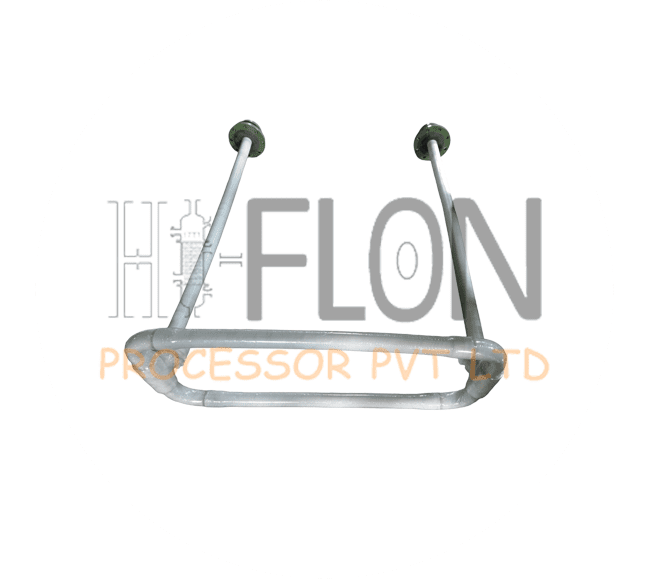

Our QC engineers determine appropriate working conditions, such as pressure rating, vacuum sustainability, and temperature, to ensure physical health. Erection guidance is also provided to ensure the quality of the long-term outcome. In addition, lining vents as per pipe standards are provided in each segment to evaluate user fouling of the segments over long-term usage. Based on various processes to fluid addition we have different design to develop.

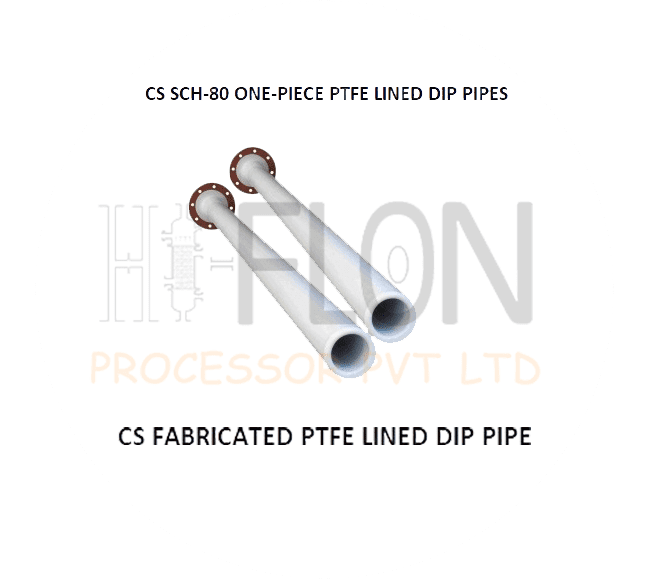

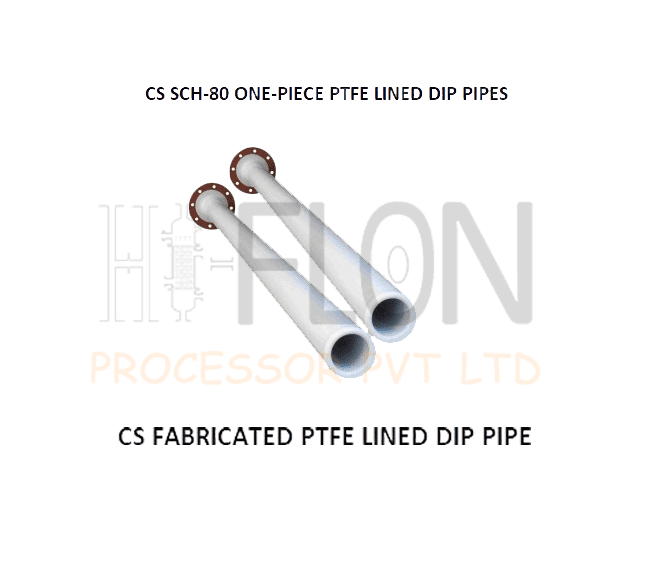

Because of the significant rotating torque of the agitator generated inside the reactor, the metallic core of the PTFE-Lined dip pipe made of seamless CS pipe designed in accordance with SCH-80.

Benefits and Features of Hi-Flon Design

Product development is subject to ANSI B 16.5 ASA#150 of IS2062 for flanges & ANSI 36.10 ASTM A-106 Grade B SCH-40/80 for Pipe with internal lining conformance to ASTM F1545.

5 MM–6 MM

Spark Test: 15 KV to check for isolated metallic contacts after lining.

Hydrostatic Pressure Test: 7.5 Kg/Cm².

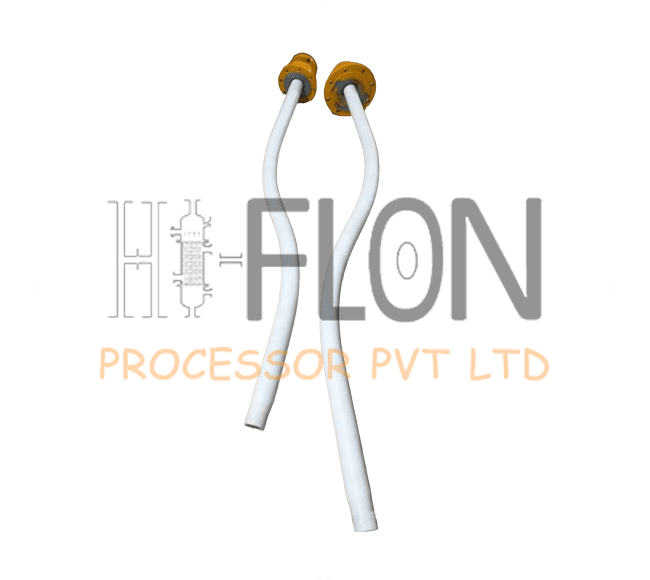

Our engineers are able to design Dip Pipes respect to Agitator Torque.

Our Technical Team also provides Torque Rating, Bending Moment based on RPM of the shaft & Motor Speed; it makes easier to recognize for suitable working conditions.

Our Engineers also guide for Installation and working after delivery at your sight by obtaining results.

In Continuous Design L: 2000 MM (25 NB to 200 NB)

In Thermal Fuse Welding Design: L: 3000 MM (25 NB to 200 NB)

Spark Test: 15 KV to check isolate metallic contacts after lining.

Hydro Test to check leakages.

Suitable For Full Vacuum -1 BAR to high pressure +6 BAR.

Location

E-503, Sumel-11, Nr Namaste Circle, Shahibaugh, Ahmedabad-380004, Gujarat.