Physical fitness is ensured by our QC engineers determining acceptable working circumstances such as pressure rating, vacuum sustainability, and temperature suitability. Erection guidance is also provided to ensure the quality of the long-term outcome. In addition, lining vents as per pipe standards are provided in each segment to evaluate user fouling of the pipe segments over long-term usage. Based on various processes to fluid addition we have different design to develop. In certain cases, CS PTFE-Lined stub end Tees of non-standard heights are provided on user request.

Benefits and Features of Hi-Flon Design:

Product development is subject to ANSI B 16.5 ASA#150 for flanges & ANSI 36.10 for pipe of ASTM A-395 Grade 60/14/18 with internal lining conformance to ASTM F1545.

4-6 MM according to the application

PTFE/PFA Lining

15 NB to 1000 NB

Spark Test: 15 KV to check for isolated metallic contacts after lining

Hydrostatic Pressure Test: 7.5 Kg/Cm²

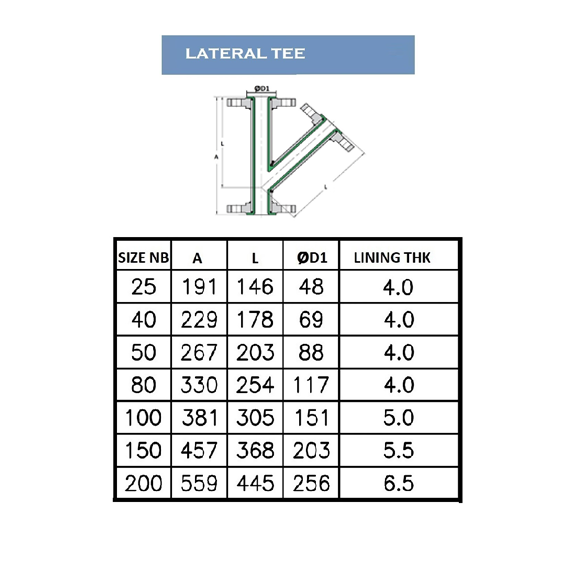

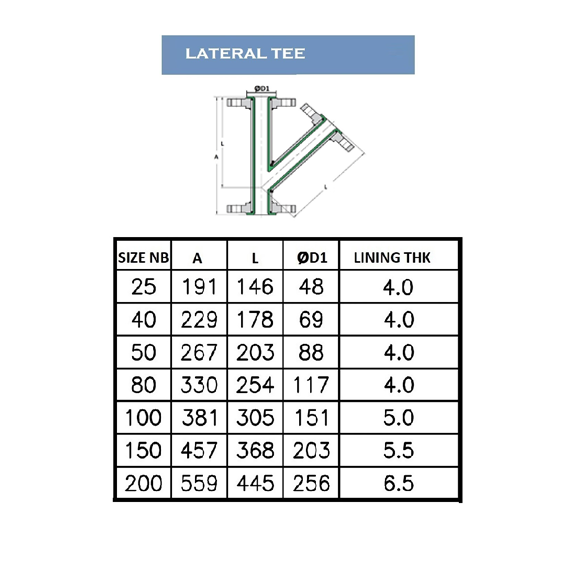

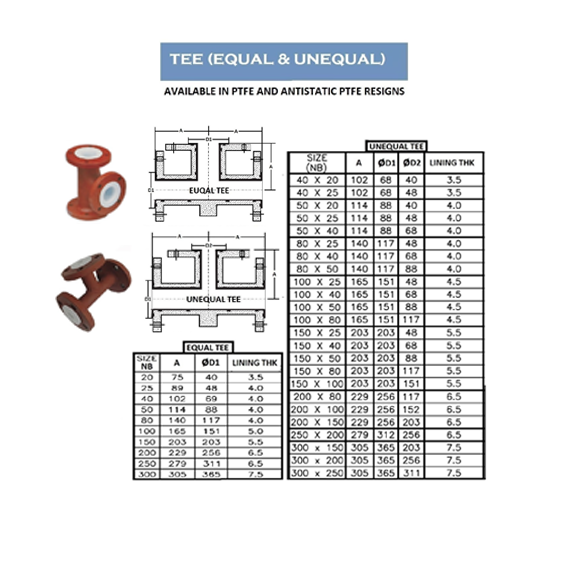

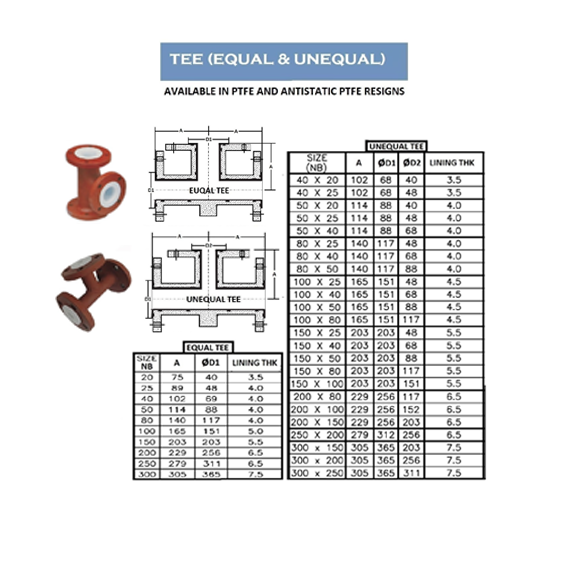

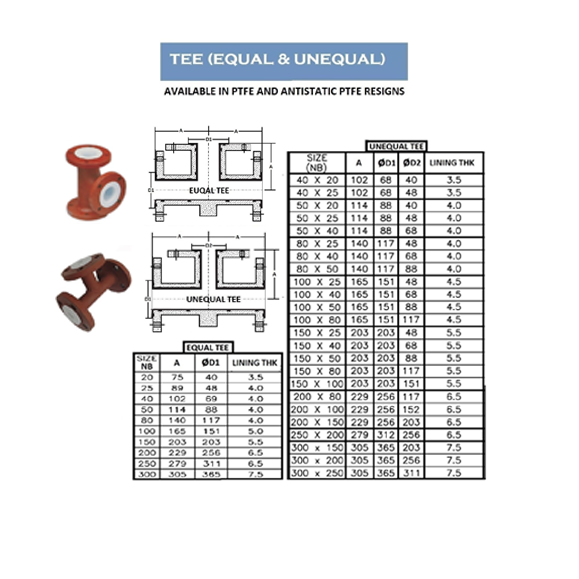

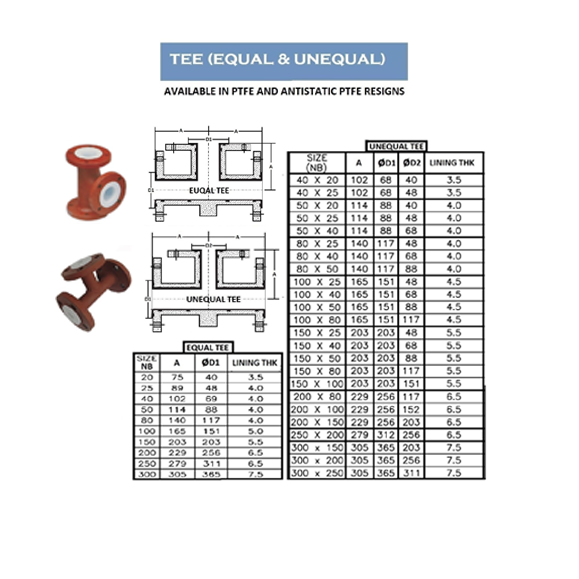

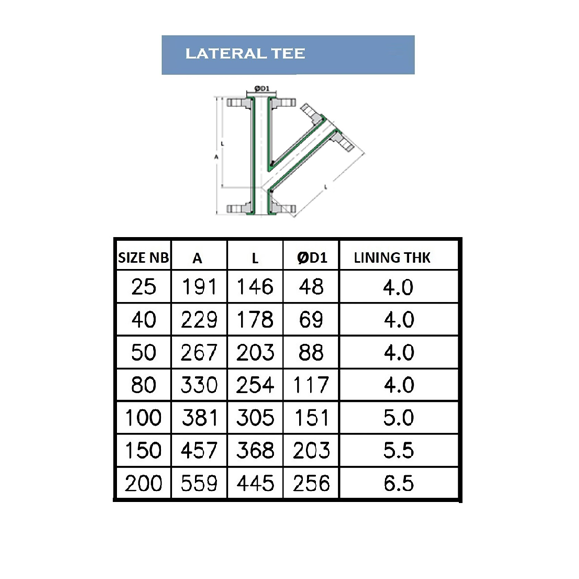

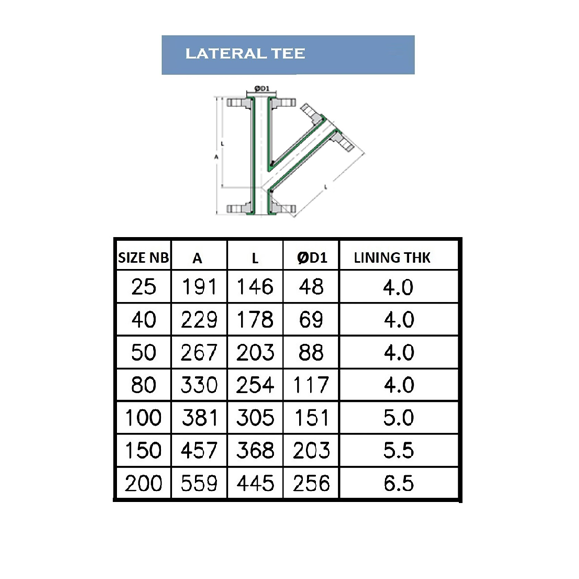

We offer various range in CS Fabricated PTFE Lined Tee or Antistatic PTFE Lined Tee in Equal & Unequal as shown in above image. CS Fabricated PTFE Lined Tee is widely used in Highly Corrosive Piping System.

Complete Development Subject to ASA # 150 Standards and Flange IS 2062 In Compliance with ANSI B 16.5 and Also available in DIN size on request.

25NB to 300 NB: PTFE Lining.

Also available in Jacketed Design.

Spark Test: 15 KV to check isolate metallic contacts after lining.

Suitable For Full Vacuum -1 BAR to high pressure +6 BAR.

Location

E-503, Sumel-11, Nr Namaste Circle, Shahibaugh, Ahmedabad-380004, Gujarat.