We provide a variety of CS-PTFE/Antistatic PTFE-lined Pipes and Jacketed Pipes for fluid flow systems. On the pipe rack of chemical facilities, CS PTFE-Lined Pipes and Spools are used to transmit fluid flow of corrosive chemicals at high temperatures. By Hi-ExtuFlon process group of manufacture, we can provide and execute functional designs suitable to the user’s application.

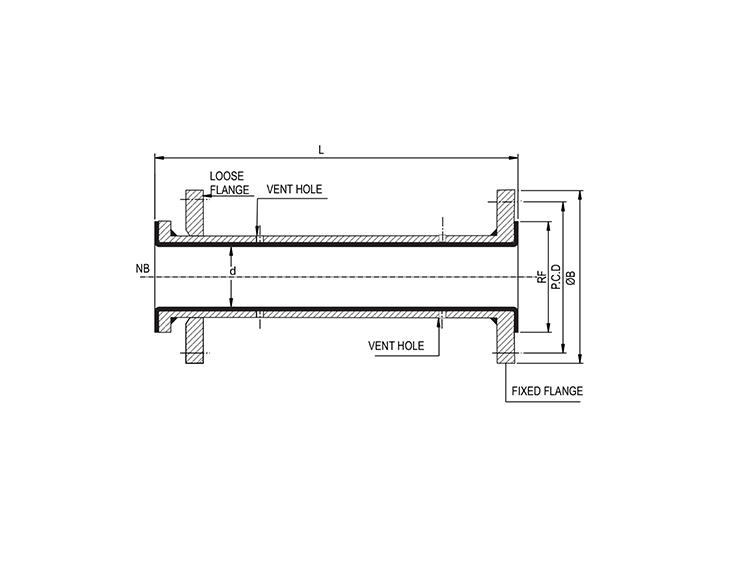

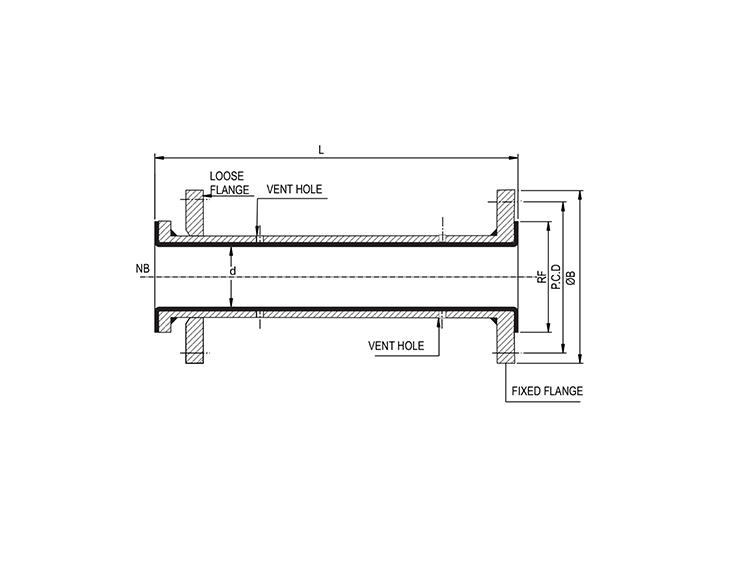

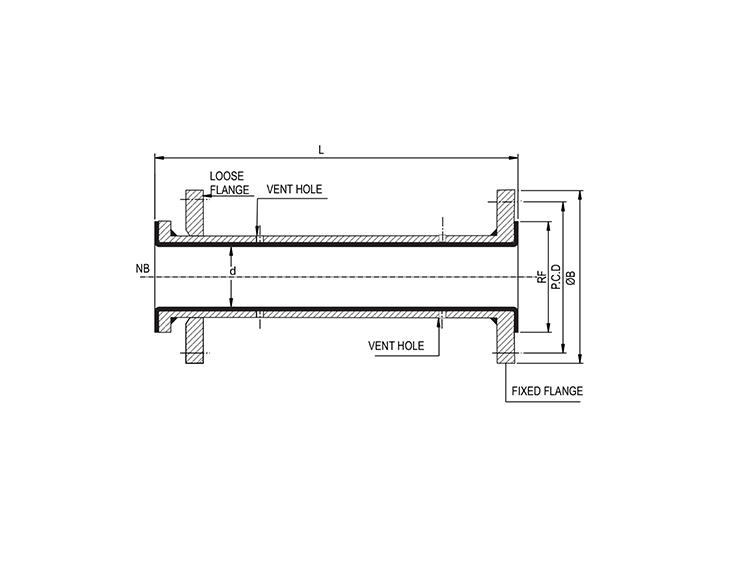

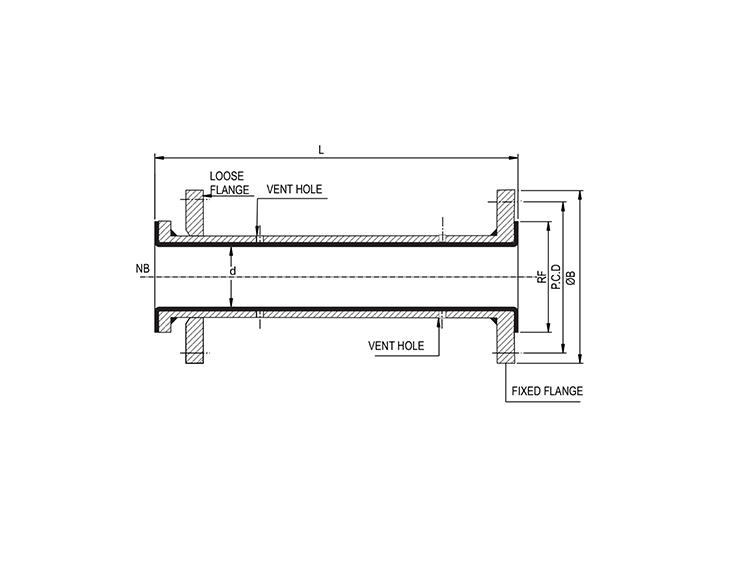

In accordance with the new plant design and pipe layout, our piping engineers and product development engineers analyze the best-suited design with a minimum of flange joints by its GAD for the process of applications. Physical fitness is ensured by our QC engineers determining acceptable working circumstances such as pressure rating, vacuum sustainability, and temperature suitability.

Erection guidance is also provided to ensure the quality of the long-term outcome. In addition, lining vents as per pipe standards are provided in each segment to evaluate user fouling of the pipe segments over long-term usage. Based on various processes to fluid addition we have different design to develop. In certain cases, PTFE Spacers and CS PTFE-Lined stub end Spools are used to shorten the length during the erection.