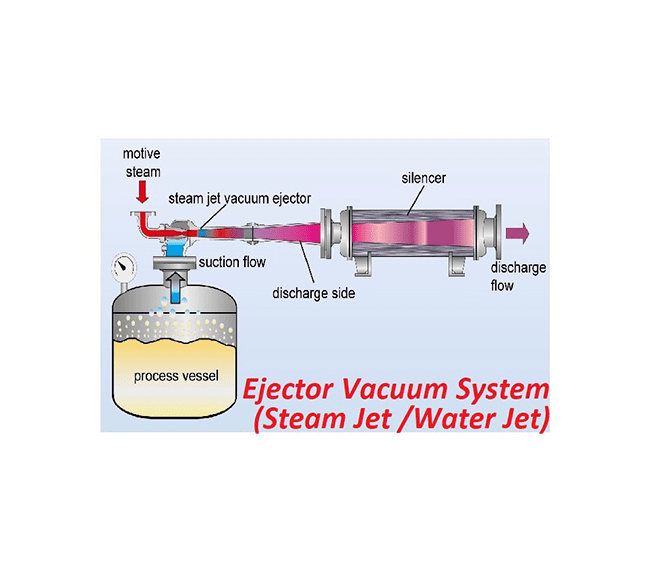

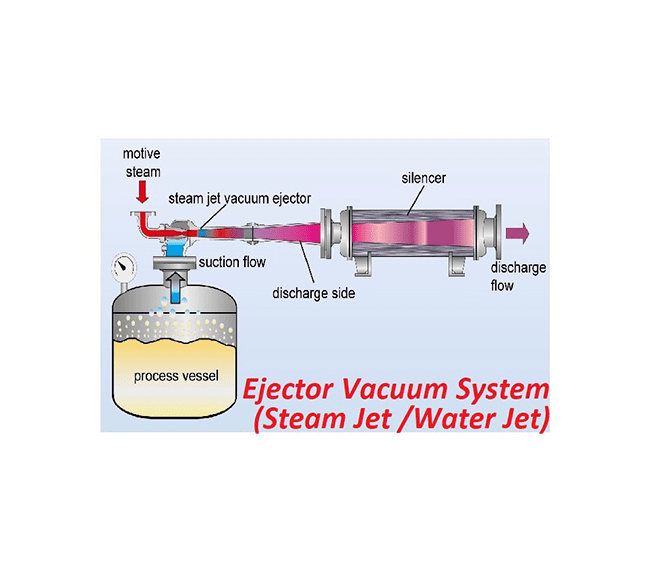

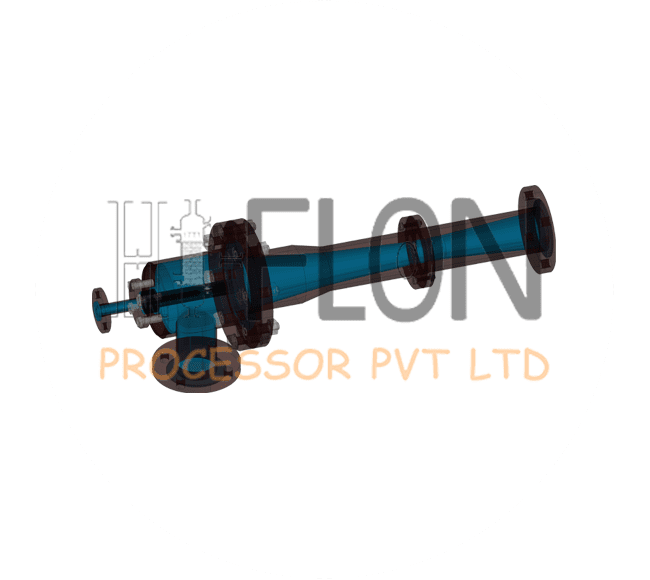

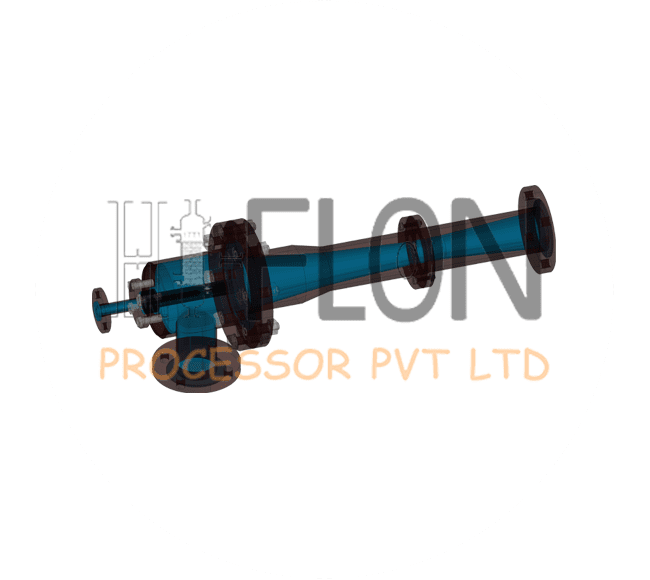

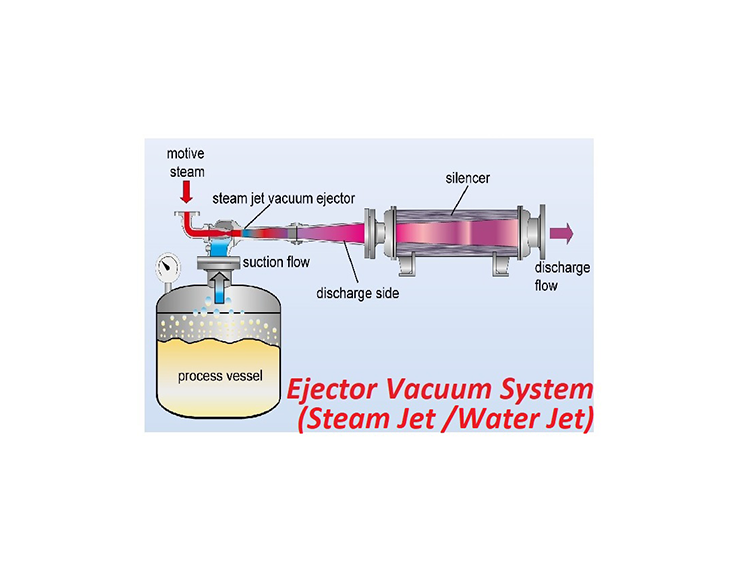

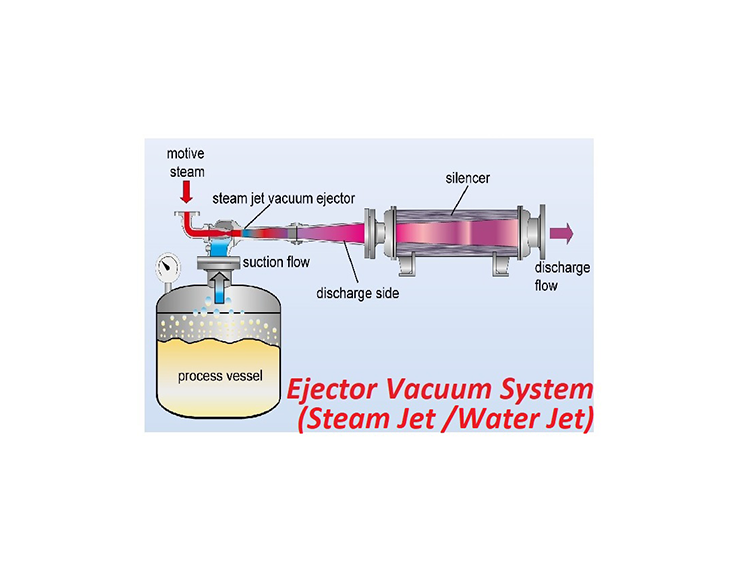

A CS-fabricated PFA-Lined Ejector Vacuum system gets used in corrosive fluid applications at high temperatures with the following function: A motive nozzle expands a relatively high-pressure fluid, such as steam or water,

which transforms the pressurized energy into velocity, or kinetic energy. Due to the high-velocity fluid jet, the downstream fluids or gases get delivered into the suction chamber from the intake nozzle.

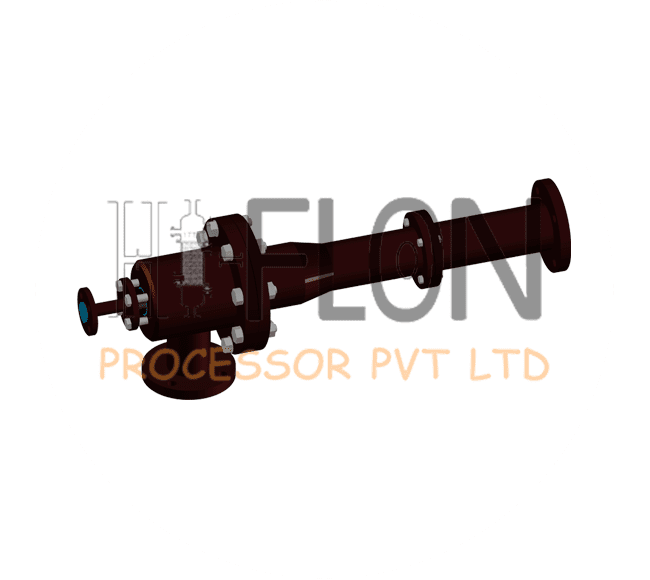

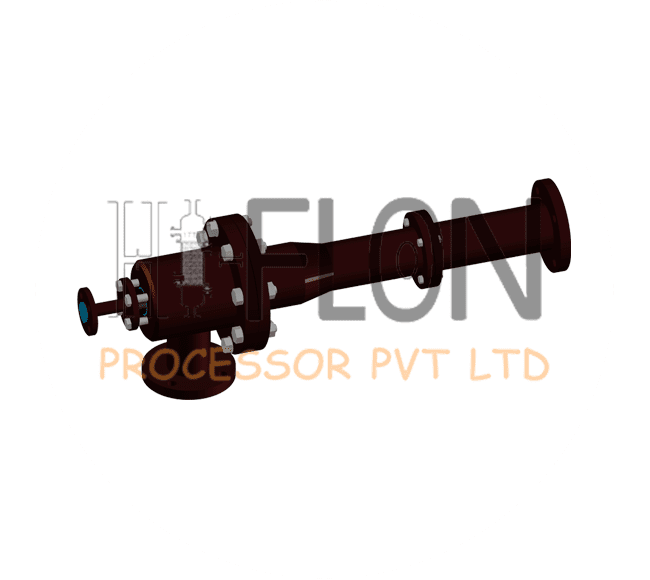

The converging and diverging passages of the ejector are to be utilized to mix and convey motive fluid and suction fluid in the required composition to the discharge pot. Our process designers and product development engineers provide process data sheets to match the best-suited design with its GAD for applications.

Physical fitness is ensured by our QC engineers determining acceptable working circumstances such as pressure rating, vacuum appropriateness, temperature suitability, heat transfer rate, and thermal conductivity. Erection guidance is also provided to ensure the quality of the long-term outcome. In addition, lining vents as per pipe standards are supplied in each segment to evaluate user fouling of the segments over long-term usage.